A project seeking to design and develop a new prosthetic hip joint is currently underway at the University of Malta. Research Support Officer and Doctoral Student DONALD DALLI explains why the MaltaHip project could potentially lead to enhanced quality of life for hip patients requiring surgery.

It’s easy to take our hips for granted. In their position at the centre of the human body, hips provide the solid foundation on which our body’s strength, motion and stability are built, enabling us to walk, dance, run, or simply stand up. Only when one or both hip bones deteriorate due to age or injury, however, causing a multitude of painful problems, do we fully appreciate their importance.

It’s easy to take our hips for granted. In their position at the centre of the human body, hips provide the solid foundation on which our body’s strength, motion and stability are built, enabling us to walk, dance, run, or simply stand up. Only when one or both hip bones deteriorate due to age or injury, however, causing a multitude of painful problems, do we fully appreciate their importance.

An ever-increasing number of patients around the world are discovering this painful truth, having to undergo hip replacement surgery in which the hip joint is entirely replaced by a prosthetic implant. Unfortunately, this drastic but long-established solution is now presenting its own difficulties. Since global populations have longer lifespans than ever before, the demand for hip prostheses is growing rapidly.

This is where a small group of researchers from the University of Malta, together with MCL Components, have decided to intervene, as the MaltaHip project team’s Research Support Officer Donald Dalli explains. “Aiming to accommodate the ever-increasing global population age, the primary goal of the MaltaHip project is to develop a prosthetic hip with potentially improved resistance to wear and tear.”

The project’s mission is a bold one, but could have significant impact on hip patients, and their doctors, worldwide if successful. Since existing prosthetic hip joints tend to create wear debris, the new implant design aims to reduce the number of clinical complications that may be attributed to wear debris, as well as their severity. By reducing an individual’s need for continued medical care in this way, in the long-term this could also reduce the monetary strain on the country’s medical sector.

The new design for the prosthetic hip joint was the brainchild of Professor Pierre Schembri Wismayer of the Department of Anatomy in the Faculty of Medicine and Surgery at the University of Malta, who leads the MaltaHip team made up of Research Support Officer and Doctoral Student Mr Dalli, along with Dr Ing Joseph Buhagiar and Dr Ing Pierluigi Mollicone of the Departments of Metallurgy and Materials Engineering and Mechanical Engineering respectively. Luke Satariano, CEO of MCL Components Ltd, together with Matthew Farrugia, Head of Product Development, will be providing the main industrial manufacturing capabilities required for the fabrication of the prosthetic hip joint prototypes.

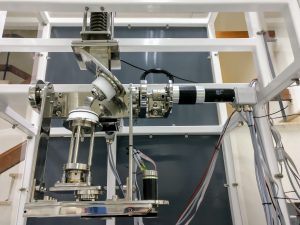

To fully realise the project’s goal of designing a new prosthetic hip joint with improved longevity, the team understood that they would need to fully test the prototype before it could be transplanted into real patients. A major aspect of the MaltaHip project thereby became designing and building an experimental simulator that would emulate the human body – equipment that didn’t yet exist in Malta.

to fully test the prototype before it could be transplanted into real patients. A major aspect of the MaltaHip project thereby became designing and building an experimental simulator that would emulate the human body – equipment that didn’t yet exist in Malta.

“We had to develop test equipment that simulates walking conditions for the prosthetic hip prototype, including testing that it can cope with three kinds of motion and up to a 300kg load, all of which a natural hip joint has to typically withstand,” continues Mr Dalli. “This was a long process in which we had to design and custom-build various components and had to solve a number of engineering problems along the way. Eventually we refined the machinery and we now have the first test equipment of its kind in Malta.”

The test equipment that has been built through MaltaHip is already award-winning, although the project is still in progress. Mr Dalli won first place with the equipment in the global ‘Speak Out for Engineering’ competition, where he had the privilege of representing Europe in New Zealand following wins across a series of European stages. The equipment also achieved an impressive second place in the Malta Innovation Awards.

The new test equipment and the new design of the prosthetic hip joint have all been made possible by the MaltaHip project’s collaboration with MCL Components and through funding of around €200,000 from The Malta Council for Science and Technology (MCST).

“Without funding and support such as that we have received from MCST, projects like MaltaHip simply could not exist,” notes Mr Dalli. “Funding enables engineering ideas to develop into tangible products, which, in time, could potentially change the world for the better.”

Read more about the project here

Project MaltaHip is financed by the Malta Council for Science & Technology, for and on behalf of the Foundation for Science and Technology, through the FUSION: R&I Technology Development Programme 2016.

Help us fund similar projects, as well as research in all the faculties, by donating to RIDT. Click here for more information on how to donate.